ANSYS Mechanical Enterprise Capabilities

Composites

|

Composite structures can impart material strength while reducing the weight of a component or product, resulting in substantial increases in energy efficiency. Engineers can essentially design the material and its shape depending on the materials used (polymers, carbon fibers, etc.) and the physical structure and sequence of the layers in the composite.

Mechanical Enterprise has both material and modeling capabilities to model composites with confidence. Layered composite structures can be modeled in the same way as they are manufactured: Layers are added to the model, and the draping, orientation and shear forces encountered by the fabric are captured and, if needed, turned into a 3-D solid model.

|

|

|

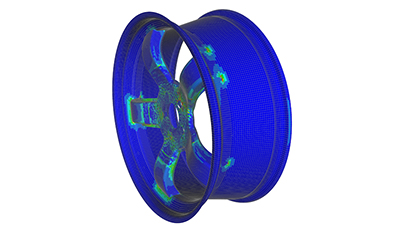

Post-processing can analyze failure criteria for a whole model in one step, identifying the failure mechanism, along with the element and layer of the model in which the failure occurs.

Modeling layered composites either in shell or solids, and with or without a core material, can be carried out with confidence. Engineers can combine composite parts with other, non-composite parts in one simulation to build whole assembly models for real engineering insight.

|