Ansys LS-DYNA is the world's most renowned general explicit dynamic simulation software that integrates finite element method and pre- and post-processing procedures, gaining high recognition and a good reputation within the industry. It can simulate different complex problems in the real world and is especially suitable for solving the short-term severe deformations of two-dimensional and three-dimensional non-linear structures, such as high-speed collisions, explosions, and large-scale permanent deformations – like stamping, metal forming, and other non-linear dynamic impacts. It can also solve heat transfer, fluid, and fluid-structure interaction problems simultaneously. Having LSTC’s LS-DYNA explicit solver closely integrated with Ansys pre-and post-processing procedures, it is more convenient and quicker to solve the virtual collision testing, Metal forging, stamping processing, breakage, and other non-linear phenomenon and their combined problems. Thus, it is widely considered as the best analysis software package in the engineering application field, having its calculation reliability proven countless times through experiments. Ansys LS-DYNA is a dedicated tool for non-linear time response analysis (such as dropping and collision), which is different from the finite element analysis tool of the implicit solver, since it uses an explicit solver that does not require convergence calculations, enabling it to process highly non-linear problems, such as dropping, collision, stamping, forging, and cutting. Engineers can conduct material failure simulations and check how cracks are generated within the materials or in between the parts and how they lead to failures. It is also easier to handle models with a large number of interactive parts or curved surfaces and to accurately simulate the power transmission between complex behaviors. Ansys LS-DYNA can effectively use multi-core resources which would reduce the computing time for the solution.

.png) |

.png) |

.png) |

|

Vehicle collision

|

Stamping and formation

|

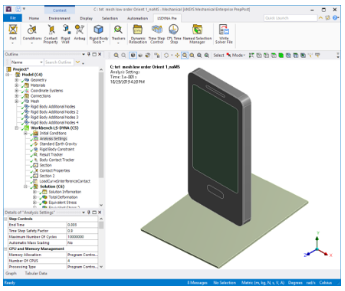

Drop analysis

|

-

Ansys Workbench LS-DYNA

|

WB LS-DYNA Interface

|

|

|

|

|

-

Rich elements, contact, and calculation methods