Member Login

Ansys Webinar - FEM Analysis for Compaction Process of Powders

2022.10.24This presentation illustrates an example of a press powder process analysis realized by co-simulation of Ansys® Rocky, Ansys LS-DYNA®, and CYBERNET Multiscale.Sim™.

Manufactured materials from powder go through many processes such as granulation, mixing, compaction, and sintering. Although compaction is one of the most critical processes in determining material properties, there aren't many detailed analyses of this process. The deformation, density, and residual stress distribution of each particle are closely related to the properties of the final product. In many cases, the DEM approach performs calculations at a realistic analysis cost when handling a vast number of particles. However, it's impossible to observe changes in the heterogeneous microstructure in detail because this method treats particles as rigid bodies. Even though the DEM approach is a practical analysis method, it does not provide sufficient information to evaluate the performance of a molded product.

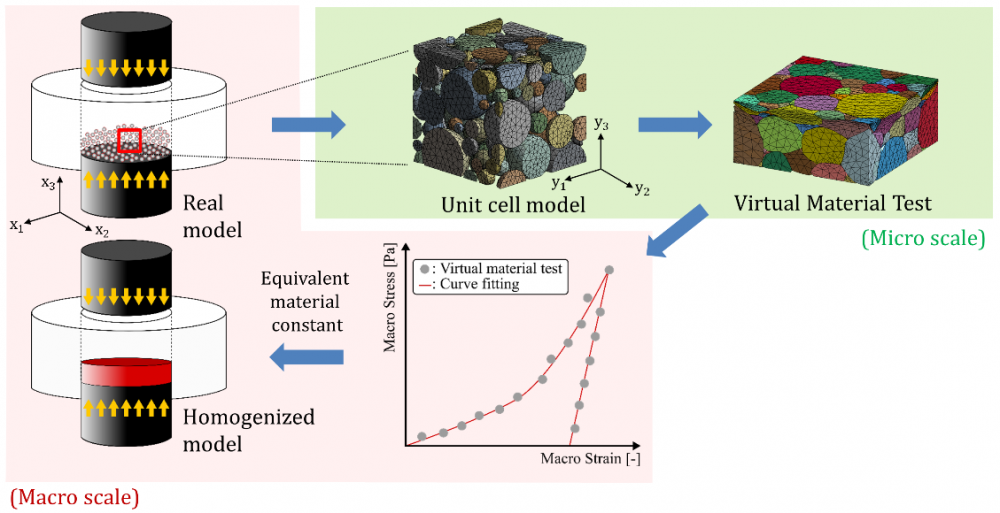

This workflow conducts FEM analysis of the compaction process at a realistic computational cost by linking multiscale and DEM analysis. Real-scale analysis can be performed while explicitly taking microstructures into account. Equivalent material constants obtained from virtual material testing homogenize the microstructure according to the Drucker Prager constitutive law. Multiscale.Sim, which is an add-in tool for Ansys Workbench, achieves the linkage between micro and macro scales.

This workflow conducts FEM analysis of the compaction process at a realistic computational cost by linking multiscale and DEM analysis. Real-scale analysis can be performed while explicitly taking microstructures into account. Equivalent material constants obtained from virtual material testing homogenize the microstructure according to the Drucker Prager constitutive law. Multiscale.Sim, which is an add-in tool for Ansys Workbench, achieves the linkage between micro and macro scales.-

Koji Yamamoto - Technology Specialist and Developer, CYBERNET SYSTEMS CO., LTD.

- Introduction to Multiscale.Sim and Ansys Rocky for the Ansys Workbench environment.

- Typical engineering and design challenges solved by combining these tools.

- General workflow for analyzing powder materials with FEM.

- How to import Ansys Rocky results into Ansys SpaceClaim® for FEM.

Who should attend:

This solution not only predicts physical phenomena during the compaction process but also visualizes problems that are unobservable in actual tests. Such data can be used for designing higher-quality materials.